This is the sixth in a series of articles that form part of our deep-dive into Six Sigma Methodology. Stay with us as we delve into the exciting and innovative world of Six Sigma.

- Cracking the Six Sigma Code

- Mastering the Define Phase in Six Sigma: A Step-by-Step Guide

- Harness Perfection: A Complete Guide To The Measure Phase

- Unraveling the Six Sigma Analyze Phase: An Essential Guide for Beginners and Practitioners

- Six Sigma Improve Phase: Driving Process Excellence through Effective Solutions

- Six Sigma Control Phase: A Practical, Essential Guide

Welcome to the exciting world of Six Sigma. Whether you’re just dipping your toes into this rich methodology or you’re already knee-deep, one thing’s for sure: Six Sigma offers a systematic approach to drastically improve business performance. And today, we’re zeroing in on one vital aspect that often flies under the radar – the Control Phase.

Now, you might be wondering, what’s so special about the Control Phase in Six Sigma? Good question! It’s the final, crucial stage in the Six Sigma DMAIC (Define, Measure, Analyse, Improve, Control) process. It ensures that all the hard work you’ve put into your project doesn’t go to waste.

But here’s the kicker: The Control Phase is more than just about maintaining the gains achieved in the Improve phase. It’s about setting up a robust system that continuously monitors the process and maintains optimal performance. Understanding this phase is not just beneficial—it’s essential for anyone eager to reap the full benefits of Six Sigma.

So, are you ready to demystify the Control Phase and make it your project’s secret weapon? Buckle up, because we’re about to embark on a deep dive into the heart of Six Sigma’s Control Phase.

Unravelling the Purpose

Let’s jump right into it. The Control Phase, often seen as the final leg of our Six Sigma journey, is where your project crosses the finish line. But what’s the grand purpose of the Control Phase in Six Sigma?

Imagine you’ve just run a marathon. You don’t simply stop running as soon as you cross the finish line, right? You gradually slow down, take deep breaths, rehydrate, and let your body adjust to a resting state. In Six Sigma terms, that’s the Control Phase – it’s your cool-down lap, your victory lap, and your preparation for the next race all rolled into one.

More technically, the Control Phase’s primary purpose is to ensure that the improvements you’ve implemented during the Improve Phase are sustained over the long term. It’s about making sure that the new, improved process continues to operate at its optimum level.

The Control Phase achieves this by setting up a control plan, monitoring systems, and response plans that kick in if performance starts to slip. Essentially, the Control Phase is your safety net. It ensures that the gains made from the earlier phases of your Six Sigma project aren’t lost due to shifts, variations, or changes in the process.

To put it simply, the Control Phase is your key to maintaining control over your improved process and, by extension, your guarantee of long-lasting, superior performance. It’s the unsung hero of any successful Six Sigma project.

Unearthing the Deliverables

Knowing the Control Phase’s purpose is all well and good, but what can you really expect to get out of this phase? What are the tangible deliverables from the Control Phase in Six Sigma that will benefit your project and, in turn, your organization?

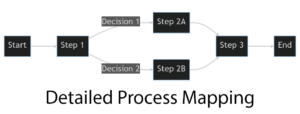

- Control Plan: This is your roadmap for maintaining the improvements you’ve made. It outlines how to monitor the process, what metrics to measure, the process owner, and what steps to take if performance falters. The control plan isn’t just a static document—it evolves with your process, ensuring you stay in control no matter what changes may come.

- Process Monitoring Systems: You need eyes on your process at all times, and that’s what process monitoring systems are for. These include dashboards, reporting tools, and statistical process control charts. They provide real-time insights into how your process is performing, so you can spot any deviation from the target performance quickly.

- Response Plan: Even with a rock-solid control plan and top-notch monitoring systems, there’s a chance your process might not perform as expected. That’s where the response plan comes in. This plan outlines the steps to take when performance doesn’t meet expectations, ensuring you can act swiftly and effectively to prevent major issues.

- Documentation: Comprehensive documentation is key to ensuring everyone involved understands the process, the control plan, and their responsibilities. This includes process maps, work instructions, and training materials.

- Validation of Improved Process: Lastly, the Control Phase delivers tangible evidence that your process has improved. This validation, usually in the form of statistical evidence, proves that the changes made have resulted in a measurable improvement.

Each of these deliverables plays a vital role in maintaining the gains from your Six Sigma project. By arming yourself with these tools, you’re taking a significant step towards ensuring the success and longevity of your improvements.

Diving into the 5 Elements of a Control Plan

Armed with an understanding of the Control Phase’s purpose and deliverables, it’s time to deep-dive into one of the essential deliverables: the Control Plan. But what exactly goes into a Control Plan in Six Sigma? Let’s break it down into its five key elements:

- Process Input/Output Variables: The first element of your Control Plan should clearly define the process input and output variables. These are the aspects of your process that are critical to ensuring quality and customer satisfaction. They are often the same metrics you identified during the Measure phase and improved during the Improve phase.

- Specifications: Specifications act as the guardrails for your process. They define the acceptable range of values for your process variables. Anything outside these limits is an indication that something in your process needs attention.

- Measurement Systems: These are the tools and methods you use to monitor your process variables. This could be anything from a simple spreadsheet to complex statistical process control software. The goal here is to gather reliable data that will help you assess the process’s performance.

- Control Methods: Control methods are your plan of action if your process starts to veer off course. It may include a range of strategies from adjusting input variables, performing preventative maintenance on equipment, or retraining personnel.

- Responsibility: Finally, every effective Control Plan needs to clearly identify who is responsible for maintaining control. This not only includes those directly overseeing the process but also individuals or teams responsible for intervening if the process starts to underperform.

Understanding and effectively implementing these elements into your Control Plan is the key to keeping your Six Sigma project on the path to success. It ensures that your improved process continues to deliver high-quality outputs, time and time again.

Frequently Asked Questions

Getting to grips with the Control Phase can seem daunting, but don’t fret. We’ve got you covered. Here are some of the most frequently asked questions that both Six Sigma beginners and practitioners often have about the Control Phase.

What are some common challenges in the Control Phase?

The Control Phase is not without its hurdles. Common challenges include resistance to change, poor documentation, lack of accountability, and inadequate monitoring systems. Overcoming these challenges often requires effective change management, comprehensive training, and a well-structured control plan.

How can I tell if the Control Phase is successful?

Success in the Control Phase is typically marked by the consistent and sustained performance of the improved process. Regular monitoring should show that the process is staying within the specified limits and producing desired results.

What are the control phase-specific tools in Six Sigma?

The Control Phase employs several specific tools, including Control Charts, Control Plans, and Standard Operating Procedures (SOPs). These tools help maintain and monitor the improved process, ensuring that the gains made are sustained in the long run.

How is the Control Phase different from the other phases in Six Sigma?

While the other phases focus on understanding, measuring, analysing, and improving the process, the Control Phase is all about maintaining these improvements. It ensures that the changes implemented are sustained and the process continues to perform at its optimal level.

Can I skip the Control Phase in Six Sigma?

It’s highly recommended not to skip the Control Phase. Doing so risks losing all the improvements made in the previous phases. The Control Phase is crucial in ensuring that the time, effort, and resources you’ve invested in your Six Sigma project deliver long-term, sustainable results.

Hopefully, these answers help to clear up some of the questions you might have had about the Control Phase. But remember, the journey to mastering Six Sigma is a continuous learning process. Keep asking, keep learning!

Conclusion

Understanding and successfully executing the Control Phase is critical for any Six Sigma project. It’s the phase that ensures the hard work done during the Define, Measure, Analyze, and Improve phases doesn’t go to waste. The Control Phase helps maintain your gains, ensuring improved processes continue to deliver high-quality outputs over time. It truly is the unsung hero of Six Sigma.

Eager to learn more? We’ve got a wealth of articles to help you delve deeper into Six Sigma’s methodologies, tools, and best practices. Continue your Six Sigma journey with us, as you explore more phases, more concepts, and more success stories from the world of Six Sigma. Let’s keep improving, one process at a time!