Data visualisation is more than just creating pleasing graphics and charts; it’s about transforming raw, numerical data into a visual context to help people understand the significance of that data. In the world of Six Sigma and Lean Six Sigma, this practice takes on a crucial role, serving as a bridge between statistical analysis and real-world decision-making.

Overview of Data Visualisation

Data visualisation is a technique that enables us to see, understand, and interpret data in a way that provides insights and helps in decision-making. By presenting data graphically, it allows practitioners to recognise patterns, trends, and even anomalies that might go unnoticed in traditional numerical presentations.

Importance in Six Sigma and Lean Six Sigma

In Six Sigma, a methodology focused on process improvement and variation reduction, data visualisation becomes an indispensable tool. It helps in:

- Identifying Key Issues: By visualising data, Six Sigma practitioners can easily pinpoint areas of inefficiency or irregularity.

- Monitoring Performance: Charts and graphs offer a visual track record of a process over time, allowing for continual assessment and improvement.

- Facilitating Communication: Visual representations can translate complex statistical data into information that’s accessible to team members across different areas of expertise.

- Enhancing Lean Principles: Within Lean Six Sigma, visualisation supports the lean principles of waste reduction and continuous improvement by making information transparent and actionable.

While there are many tools available for data visualisation, MS Excel stands out for its accessibility and familiarity. Excel’s robust features offer both beginners and experienced Six Sigma practitioners the ability to create compelling visualisations like control charts and Pareto charts. The step-by-step instructions in the upcoming sections will guide you through creating these visualisations using MS Excel.

In This Guide

Understanding the Concepts of Six Sigma Data Visualisation

Data visualisation in Six Sigma is not a one-size-fits-all approach. Instead, it’s a tailored method that facilitates a deeper understanding of processes, helps in problem-solving, and supports continuous improvement. Here, we’ll explore the underlying concepts that make data visualisation an essential aspect of Six Sigma.

What is Data Visualisation in Six Sigma?

In Six Sigma, data visualisation refers to the graphical representation of data to understand variations, trends, and insights within processes. It transforms raw numerical data into visuals like charts, graphs, and diagrams, making complex information more digestible. This is not just about aesthetic appeal but about making data actionable.

Why is Data Visualisation Essential in Six Sigma?

- Quick Insights: Visualising data allows practitioners to quickly identify areas that need improvement, saving time and resources.

- Decision Support: Graphics and charts enable data-driven decisions, promoting objectivity over gut feeling.

- Improves Collaboration: Visual data can be shared across different teams, fostering collaboration and a shared understanding of process performance.

- Aligns with Continuous Improvement: Six Sigma aims for continuous improvement, and data visualisation supports this by providing a clear picture of progress and areas of focus.

Connection between Lean Six Sigma and Data Visualisation

Lean Six Sigma, an approach that combines Six Sigma’s focus on quality with Lean’s emphasis on efficiency, further emphasizes the importance of data visualisation:

- Waste Reduction: By visually highlighting inefficiencies, Lean Six Sigma practitioners can target areas of waste, such as defects or overproduction.

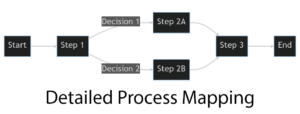

- Enhances Process Flow: Visual tools like process maps facilitate a better understanding of how a process flows, allowing for optimisation and streamlined operations.

- Supports the DMAIC Methodology: Throughout the DMAIC (Define, Measure, Analyse, Improve, Control) cycle, data visualisation plays a critical role in understanding, analysing, and controlling processes.

In an environment where precision and efficiency are paramount, the ability to visualize data becomes a powerful tool. The concepts and principles highlighted in this section form the foundation for the practical applications we will explore next, using common Six Sigma visualisation techniques like control charts and Pareto charts in MS Excel.

Common Data Visualisation Techniques in Six Sigma

In Six Sigma, specific data visualisation techniques provide valuable insights into process performance and variation. Among these, control charts and Pareto charts are widely used. Here’s how you can create and interpret these visualisations using MS Excel.

Control Charts

Control charts are vital in monitoring process stability and identifying variations. They help to distinguish between common cause variation (inherent in the process) and special cause variation (due to external factors).

Explanation and Significance

- Understanding Variation: Control charts visualize data over time, helping you identify trends, shifts, or abnormal patterns.

- Process Control: By monitoring the process, you can take corrective actions if the data points fall outside the control limits.

Step-by-step Guide to Creating a Control Chart Using MS Excel

- Gather Data: Collect a set of generalized raw data related to the process you are monitoring.

- Calculate Averages and Limits: Determine the mean, upper control limit (UCL), and lower control limit (LCL).

- Plot the Data: Use Excel’s chart functions to plot the data points, mean, UCL, and LCL.

- Interpret the Chart: Look for patterns or points outside the control limits, which might indicate potential issues.

Pareto Charts

Pareto charts are essential in prioritizing problems by displaying them in descending order of significance, aligning with the principle that 80% of problems are caused by 20% of the causes.

Explanation and Significance

- Prioritizing Issues: Pareto charts help in focusing on the most significant problems, thus optimizing resource allocation.

- Problem-Solving Tool: They assist in identifying key areas for improvement and align with the Six Sigma DMAIC cycle.

Step-by-step Guide to Creating a Pareto Chart Using MS Excel

- Identify Categories and Frequencies: List the issues or categories and their corresponding frequencies or impacts.

- Sort the Data: Arrange the data in descending order.

- Create the Chart: Utilize Excel’s Pareto chart function to visualize the data.

- Analyse the Results: Use the chart to identify the major contributors to the problem and focus your improvement efforts.

By understanding and utilizing these techniques, Six Sigma practitioners can monitor, analyse, and improve processes efficiently. The step-by-step instructions and examples provided offer a hands-on approach to creating these valuable visualisations using MS Excel.

Subscribe to our newsletter!

Creating Six Sigma Visualisations in MS Excel

MS Excel is a powerful tool for Six Sigma practitioners, offering various functionalities for creating compelling data visualisations like control charts and Pareto charts. This section will provide you with a step-by-step guide for creating these essential visualisations, catering to both beginners and experienced practitioners.

A. Creating Control Charts in MS Excel

Control charts are essential for monitoring process stability. Here’s a step-by-step guide:

- Open MS Excel: Start with a blank workbook.

- Enter the Data: Input week numbers in column A and performance data in column B.

- Calculate Averages and Control Limits: Use Excel formulas to calculate the mean, upper control limit (UCL), and lower control limit (LCL).

- Create the Chart: Select the data and use the ‘Insert Chart’ option to plot the control chart.

- Customize the Chart: Add labels, gridlines, and control limit lines for clarity.

- Analyse the Results: Use the chart to identify trends or variations that may require further investigation.

B. Creating Pareto Charts in MS Excel

Pareto charts help prioritize issues by significance. Here’s how to create one:

- Open MS Excel: Start with a blank workbook.

- Enter the Data: Input the categories in column A and complaints data in column B.

- Sort the Data: Arrange the data in descending order.

- Create the Pareto Chart: Select the data and use the ‘Insert Chart’ option to create a Pareto chart.

- Customize the Chart: Adjust labels and formatting to enhance readability.

- Analyse the Results: Use the chart to focus on the key areas that require improvement.

Tips for Effective Six Sigma Visualisation in MS Excel

- Use Clear Labels: Always label axes and legends for clarity.

- Select Appropriate Scales: Choose scales that reflect the data accurately.

- Keep it Simple: Avoid unnecessary decorations that may distract from the data.

- Regularly Update Charts: Keep the charts up to date with the latest data for continuous monitoring.

Advantages of Using MS Excel in Six Sigma

- Accessibility: Excel is widely available, making it a practical choice for many organisations.

- Ease of Use: With intuitive functions and features, it’s suitable for both beginners and advanced users.

- Customization: Excel offers numerous customization options, enabling users to tailor charts to their specific needs.

By using MS Excel for Six Sigma data visualisation, practitioners can create insightful charts and graphs that provide valuable insights into process performance. This hands-on guide empowers both beginners and experienced Six Sigma practitioners to utilize Excel’s robust features effectively.

Frequently Asked Questions

1. What Role Does Data Visualisation Play in Six Sigma?

Data visualisation in Six Sigma serves as a powerful tool for understanding and communicating complex data. By transforming numerical data into visual formats like control charts, Pareto charts, and histograms, practitioners can easily identify trends, variations, and areas for improvement, making data-driven decisions more accessible and actionable.

2. How Do Control Charts Help in Monitoring Six Sigma Processes?

Control charts are fundamental in Six Sigma for visualizing process performance over time. They help in distinguishing between common and special cause variations, enabling practitioners to identify abnormal patterns and take corrective actions. This real-time monitoring ensures that the process remains within control limits, ensuring quality and efficiency.

3. Why Are Pareto Charts Significant in Six Sigma?

Pareto charts are vital in Six Sigma for prioritizing problems or defects. By displaying issues in descending order of significance, Pareto charts align with the principle that a small number of causes are often responsible for most problems. This visualisation aids in focusing resources on areas that will yield the most significant improvement, aligning with Lean Six Sigma principles.

4. How Can MS Excel Facilitate Data Visualisation in Six Sigma?

MS Excel is a widely accessible tool that supports various data visualisation techniques essential in Six Sigma. Its user-friendly functions allow practitioners to create control charts, Pareto charts, histograms, and more. With customizable features and intuitive design, Excel empowers both beginners and experienced Six Sigma practitioners to create insightful visualisations.

5. What Are Some Best Practices for Effective Data Visualisation in Six Sigma?

Effective data visualisation in Six Sigma requires clarity, accuracy, and simplicity. Key best practices include:

- Using clear labels and legends

- Selecting appropriate scales and colour schemes

- Keeping visuals simple and free from distractions

- Regularly updating charts with current data

- Utilizing tools like MS Excel for customization and ease of use

The Importance of Data Visualisation in Six Sigma

Data visualisation is not merely an aesthetic aspect of Six Sigma; it’s an essential tool that offers a deeper understanding and actionable insights.

A. Making Complex Data Understandable

Six Sigma often involves complex data analysis. Visualisations like control charts and Pareto charts translate this complexity into understandable insights, aiding in interpretation and decision-making.

B. Enhancing Communication

Visualisations facilitate communication among team members and stakeholders. They allow for a common understanding and alignment, fostering collaboration and streamlined processes.

C. Facilitating Continuous Improvement

Through ongoing monitoring with visualisations, Six Sigma practitioners can promptly identify variations and trends. This timely detection enables continuous improvement, aligning with Lean Six Sigma principles.

D. Accessibility Through Tools like MS Excel

Tools like MS Excel make data visualisation accessible to beginners and experienced practitioners alike. With step-by-step guides and sample data, this article demonstrates how MS Excel can be an ally in Six Sigma data visualisation.

Conclusion

Data visualisation in Six Sigma is a critical aspect that transcends numbers, offering visual insights for better understanding, communication, and decision-making. Tools like MS Excel, with its accessibility and customization features, empower practitioners to create insightful visualisations like control charts and Pareto charts.

This guide has aimed to provide Six Sigma beginners and practitioners a comprehensive understanding of data visualisation in Six Sigma, focusing on practical examples and step-by-step instructions. From general concepts to specific visualisations, and from the role of MS Excel to best practices, the goal has been to make the whole concept accessible and informative.

Subscribe to our newsletter!