Welcome to your ultimate guide on mastering the Design of Experiments (DOE) in the realm of Six Sigma! This is an essential read for those looking to deepen their understanding of this potent tool, and significantly improve the efficiency and effectiveness of their Six Sigma projects.

Design of Experiments, or DOE as it’s often abbreviated, is a systematic, rigorous approach to investigating the relationship between different variables in a process. When leveraged effectively, DOE can be a powerful ally in decision making and problem solving.

But what happens when you merge the strategic methodology of Six Sigma with the insights of DOE? The result is a powerful union that has the potential to take your process improvement projects to new heights.

In this comprehensive guide, we’ll delve deep into the world of DOE, offering explanations, examples, and strategies to help you truly grasp this concept and its application within Six Sigma.

Stay tuned as we unravel the intricacies of the Design of Experiments and demonstrate its crucial role in Six Sigma’s Improve phase.

In This Guide

Unravelling the Design of Experiments: The What and Why

To truly master the Design of Experiments (DOE) within the Six Sigma framework, we must first understand what DOE is and why it is such an integral tool in research and process improvement.

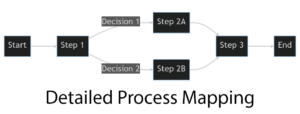

DOE is a strategic approach that allows researchers to systematically plan, execute, and interpret controlled tests. This method goes beyond merely observing natural phenomena, delving deeper to manipulate factors to observe the resulting effects.

Consider this: Suppose you’re a quality manager at a manufacturing plant, and you suspect that the speed of a machine and the quality of raw material used might be influencing the quality of your final product. In this case, you could use DOE to run experiments altering machine speeds and using different quality materials to see the effects on your final product.

This isn’t just about understanding cause and effect, though. DOE helps us quantify relationships, giving us more than just a binary ‘yes or no’ answer. Using DOE, we can analyse multiple factors simultaneously, creating a more detailed picture of the process.

The primary purpose of DOE is to identify the critical factors influencing a process and to uncover the interactions between these factors. The beauty of DOE lies in its systematic approach that not only reduces the time taken for experimentation but also makes optimal use of resources, ensuring the highest possible level of efficiency.

Understanding DOE is like being handed the keys to a potent, multi-faceted toolkit. With it, you can optimise processes, reduce variability, and drive impactful decisions. No wonder, then, that DOE finds its place in diverse fields ranging from industrial manufacturing to software development, and of course, in methodologies like Six Sigma, where reducing process variability is the name of the game.

Six Sigma and DOE: A Strategic Partnership

In the world of quality management, Six Sigma stands tall as a methodology designed to improve processes by minimising defects and reducing variability. When DOE becomes part of this equation, it transforms into an even more powerful tool for optimisation and improvement.

Six Sigma is a data-driven approach that follows a structured methodology – DMAIC. This acronym stands for Define, Measure, Analyse, Improve, and Control. These stages form the blueprint for any Six Sigma project, guiding practitioners in their quest for improved quality and efficiency.

DOE plays a pivotal role in the Analyse and Improve stages of DMAIC. It helps Six Sigma professionals dissect complex processes and understand the intricate relationships between various factors. It’s all about getting to the heart of the process and shining a light on what really matters.

Unleashing the Power of DOE in Six Sigma

For instance, in the Analyse phase, you might use DOE to identify which factors are significantly impacting your process output. Armed with this knowledge, you can then move into the Improve phase, using DOE to optimise these key factors for better performance.

By systematically altering input variables and studying the resulting process outputs, you can gain deep insights into the behaviour of your processes. This not only helps in improving the existing process but also provides a sturdy foundation for predictive modelling, where you can anticipate how changes will impact future performance.

The incorporation of DOE into the Six Sigma framework opens new avenues for optimisation, pushing the boundaries of what’s possible in process improvement. As we delve deeper, we’ll take a closer look at the role of DOE in the Improve phase of a Six Sigma project, using real-world examples to bring the concept to life.

Role of DOE in Six Sigma: The Improve Phase

Six Sigma’s DMAIC framework is a road map for quality improvement. As we’ve discussed, the Design of Experiments (DOE) is a particularly valuable tool during the Analyse and Improve stages of this model.

DOE in the Analyse Phase

In the Analyse phase, you’re tasked with identifying the root causes of process problems. Here, DOE provides a systematic way to dissect the problem and highlight the critical factors influencing your process outputs. It’s like turning on a spotlight in a dark room, suddenly revealing the key elements you need to focus on.

For example, you might be trying to reduce the defect rate in a product manufacturing line. Using DOE, you could explore various factors like machine calibration, operator skill level, raw material quality, and more to find out which ones are significantly impacting your defect rate.

DOE: Powering Up the Improve Phase

The Improve phase of DMAIC is where the real magic happens. It’s about using the insights gleaned from the Analyse phase to bring about positive change. DOE comes into play once again here, enabling you to find the optimal conditions for your key process variables.

Continuing the example above, let’s say you discovered that machine calibration and raw material quality are your critical factors. In the Improve phase, you could use DOE to find the ideal machine calibration settings and the best quality of raw material to minimise defects.

DOE’s role in the Improve phase is not only about optimizing the process but also about making robust predictions for future performance.

Mastering DOE in Six Sigma: Pro Tips

Understanding the fundamentals of Design of Experiments (DOE) and its application within the Six Sigma framework is a powerful first step. But how can you ensure you’re getting the most out of this potent tool? Here are some pro tips to guide you on the path to mastery.

Learn the Lingo

In the world of DOE, terminology matters. Take time to familiarise yourself with key terms such as factors, levels, response, and interactions. Understanding the language of DOE will make planning, executing, and analysing your experiments much more manageable.

Embrace Software Solutions

DOE calculations can get complex, especially when dealing with multiple factors and interactions. Software solutions like Minitab, JMP, and Design Expert can help crunch the numbers, allowing you to focus on understanding and interpreting the results.

Stay Organised

A well-structured DOE is easier to manage and analyse. Keep careful track of your experimental runs and results, making sure to note any unexpected occurrences. This thorough record-keeping will pay dividends when it comes to analysing your data and drawing valid conclusions.

Don’t Forget the Real World

While DOE gives you the power to optimise your processes in a controlled environment, always remember to verify your results under real-world conditions. This verification ensures your process improvements hold up in the day-to-day grind of your operation.

Mastering DOE in Six Sigma is like unlocking a new level in your quest for quality improvement. Practice these tips, stay curious, and you’ll be well on your way to becoming a DOE pro!

Frequently Asked Questions about DOE in Six Sigma

When it comes to Design of Experiments (DOE) within the Six Sigma framework, several questions might be swirling around in your head. We’ve compiled some of the most common inquiries and provided straightforward answers to help solidify your understanding.

What’s the Main Purpose of DOE in Six Sigma?

The primary purpose of DOE in Six Sigma is to identify the significant factors that impact a process’s output and understand the interactions between these factors. With this knowledge, you can optimise your process during the Improve phase of DMAIC to reduce variability and improve quality.

Can DOE Be Used in All Phases of Six Sigma?

DOE is most used in the Analyse and Improve phases of the Six Sigma DMAIC model. However, the principles of experimental design can be useful in other phases as well. For example, during the Control phase, DOE can help you determine the most effective control variables to maintain your improved process.

Subscribe to our newsletter!

How Complex Is DOE?

DOE can be simple or complex, depending on the nature of your process and the number of factors you’re investigating. Software tools can assist with more complex designs, making it manageable even for those new to DOE.

Is DOE Only for Manufacturing Processes?

Absolutely not! While DOE is often used in manufacturing, its principles can be applied to any process, whether it’s software development, customer service, or even cooking! If there’s an outcome you can measure and factors you can manipulate, you can use DOE.

What If My DOE Doesn’t Give Clear Results?

Remember, a ‘failed’ experiment isn’t really a failure if you’ve learned something. If your DOE doesn’t yield clear results, take a step back and review your experiment. Were there confounding variables you didn’t account for? Was there a problem with the data collection? Use these learnings to refine your next DOE.

DOE in Six Sigma is a fascinating and powerful tool. Keep asking questions, keep learning, and you’ll keep improving!

Wrapping Up: DOE, The Six Sigma Superpower

Design of Experiments (DOE) is a potent tool in the world of Six Sigma, providing a systematic and efficient way to delve into process intricacies. Whether you’re working on manufacturing efficiency, improving service quality, or anything in between, DOE holds the key to unlocking valuable insights and making meaningful improvements.

Empower Your Six Sigma Journey with DOE

We’ve journeyed through the basics of DOE, understood its purpose, and seen how it integrates with the Six Sigma methodology. We’ve also provided tips to master DOE and answered frequently asked questions. As you absorb this knowledge, you’re already on your way to becoming more proficient in Six Sigma and DOE.

Embrace the Power of Data and Experimentation

Remember, at its heart, Six Sigma is all about reducing variability and improving process performance. With DOE, you can shine a spotlight on the factors that truly matter, optimising your processes based on concrete data and careful experimentation.

Never Stop Learning

Just like the Six Sigma journey, the path to mastering DOE is one of continuous learning and improvement. Embrace the journey, stay curious, and keep pushing for better performance. As you do, you’ll find yourself armed with the skills to make a tangible difference in your organization.

Take the Next Step in Your Six Sigma Journey

Now that you’re armed with a deeper understanding of Design of Experiments (DOE) in Six Sigma, you’re ready to put that knowledge into action. Remember, theoretical understanding is only half the battle – the real learning comes when you apply these concepts to your own processes.

Whether you’re a Six Sigma beginner or an experienced practitioner, we invite you to delve deeper into our wide range of resources. Explore our comprehensive guides, and practical articles – all designed to support you in your Six Sigma journey.

Remember, each step you take is a move towards improved quality, greater efficiency, and better business outcomes. So why wait? Start applying DOE to your Six Sigma projects today and witness the transformational power of data-driven decision making.

Subscribe to our newsletter!