Welcome to the fascinating world of Six Sigma, a proven methodology that is transforming how businesses and professionals approach process improvement. Whether you are a corporate professional new to Six Sigma or someone curious about optimizing workflows, this guide is designed for you.

What is Six Sigma?

Six Sigma is a set of tools and techniques aimed at enhancing process quality and efficiency. Rooted in statistical analysis, it seeks to identify and remove the causes of defects and variations, ensuring that processes are as close to perfection as possible.

Understanding DMAIC

At the core of Six Sigma lies the DMAIC methodology, an acronym for Define, Measure, Analyse, Improve, and Control. It provides a structured approach to problem-solving, enabling organizations to reach their goals systematically.

Lean Six Sigma Overview

Lean Six Sigma combines the principles of Lean manufacturing with Six Sigma methodologies. It emphasizes not only the elimination of defects but also the reduction of waste and inefficiencies, creating a more streamlined process.

This guide offers an in-depth exploration of Six Sigma’s various belt levels, the roles and responsibilities attached to each, and the qualifications required. We will also delve into how Six Sigma can be a powerful tool for corporate professionals embarking on the process improvement journey. Whether you’re a beginner or a practitioner, there’s something valuable for you here.

In This Article

Understanding Six Sigma

What is Six Sigma?

Six Sigma is more than just a buzzword in the business world; it’s a comprehensive methodology focused on achieving near-perfect results in process improvement. By using statistical tools and a structured approach, Six Sigma aims to reduce variations and defects in processes, leading to higher efficiency and customer satisfaction.

DMAIC Methodology Explained

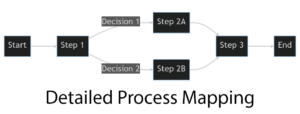

The DMAIC methodology is a central part of the Six Sigma approach. It’s a five-phase process that provides a roadmap for improving any business process:

- Define: Clearly state the problem and set measurable goals.

- Measure: Gather data and establish baseline performance.

- Analyse: Identify the root causes of variations or defects.

- Improve: Develop and implement solutions to address the root causes.

- Control: Maintain the improvements and ensure long-term success. By following DMAIC, organizations can systematically tackle complex issues, making it a powerful tool for continuous improvement.

Lean Six Sigma Overview

Lean Six Sigma merges the Lean methodology’s focus on waste reduction with Six Sigma’s emphasis on quality improvement. While Six Sigma targets variations and defects, Lean is all about speeding up processes by eliminating waste. Together, they form a holistic approach to improving efficiency and effectiveness. The principles of Lean Six Sigma are:

- Eliminate Waste: Remove unnecessary steps, resources, or activities.

- Enhance Value: Focus on what adds value to the customer.

- Streamline Processes: Create smooth, efficient workflows.

- Continuously Improve: Always seek ways to make things better. Lean Six Sigma provides a framework for achieving excellence, offering businesses a pathway to thrive in a competitive environment.

Six Sigma Belt Levels

White and Yellow Belts

White Belt: The starting point in the Six Sigma journey, White Belt training introduces the basic concepts and terminology. Ideal for anyone wanting a general understanding, it requires no prior experience.

Yellow Belt: A step further, the Yellow Belt focuses on more specific tools and techniques. It’s suitable for team members involved in minor Six Sigma projects, requiring basic knowledge and some hands-on experience.

Green Belt

Green Belt: This level represents a more advanced understanding. Green Belts work on projects within their functional area and often lead smaller project teams. They collaborate with Black Belts, requiring in-depth training and experience.

Black Belt

Black Belt: Black Belts are experts in Six Sigma methodologies. They lead major projects, provide training, and act as mentors to Green Belts. Achieving this level requires extensive training, successful project completion, and demonstrated leadership skills.

Master Black Belt

Master Black Belt: The pinnacle of Six Sigma mastery, Master Black Belts hold a strategic role. They guide the organization’s Six Sigma program, develop training materials, and serve as in-house consultants. This level demands a proven track record of success in Six Sigma projects and strong leadership abilities.

Responsibilities and Roles for Each Belt

Roles of White and Yellow Belts

- White Belts: Typically involved in localized problem-solving, White Belts assist in Six Sigma projects within their daily roles but may not lead projects. They understand Six Sigma terminology and provide support where needed.

- Yellow Belts: Playing a more active part, Yellow Belts participate in small project teams and assist Green and Black Belts. Their responsibilities may include data collection, process mapping, and basic analysis.

Green Belt Responsibilities

- Green Belts: Often considered the project workhorses, Green Belts lead small to medium projects within their department. They apply Six Sigma tools, gather and analyse data, coordinate with Black Belts, and ensure that improvements are sustained.

Black and Master Black Belt Duties

- Black Belts: As project leaders for large-scale efforts, Black Belts design and implement significant process improvements. They train and mentor Green Belts, facilitate cross-functional cooperation, and ensure alignment with organizational goals.

- Master Black Belts: Taking on a more strategic role, Master Black Belts oversee the organization’s entire Six Sigma program. They develop training curriculum, guide Black Belts, foster organizational change, and advise senior management on Six Sigma strategies.

Experience and Certifications

Experience Requirements for Each Belt

- White Belt: No prior experience needed. Ideal for individuals seeking basic awareness.

- Yellow Belt: Some exposure to Six Sigma concepts is beneficial but not mandatory.

- Green Belt: Often requires successful completion of at least one project and a firm grasp of Six Sigma tools.

- Black Belt: Several years of experience in Six Sigma projects, along with proven leadership abilities.

- Master Black Belt: Extensive experience, including successful leadership of multiple large-scale projects and mentorship of Black Belts.

Certification Process and Providers

Certification is an essential part of the Six Sigma journey, validating an individual’s skills and understanding of Six Sigma methodologies.

- White and Yellow Belts: Many providers offer online courses, with completion certificates issued after passing an examination.

- Green Belt: Certification typically involves completing a training course, passing an exam, and successfully leading a project.

- Black Belt: More rigorous, requiring extensive training, an exam, and a portfolio of successfully completed projects.

- Master Black Belt: The most demanding level, involving specialized training, multiple exams, and evidence of significant contributions to Six Sigma initiatives.

Popular training providers include ASQ, IASSC, and local universities, among others. Selecting the right provider depends on specific needs, industry recognition, and alignment with career goals.

Subscribe to our newsletter!

Applying DMAIC and Lean Six Sigma in the Corporate World

DMAIC in Business Process Improvement

DMAIC is a fundamental methodology in Six Sigma, serving as a structured approach to problem-solving. In the corporate world, it aids in:

- Identifying Problems: Through the Define phase, organizations can pinpoint specific issues and set measurable goals.

- Analysing Performance: By Measuring and Analysing, businesses can understand root causes, enabling targeted improvements.

- Implementing Solutions: The Improve and Control phases ensure that the solutions are both effective and sustainable. Applying DMAIC ensures that improvements are data-driven and aligned with organizational objectives, making it a preferred approach in various industries.

Lean Six Sigma in Enhancing Efficiency

Lean Six Sigma takes the process improvement a step further by integrating Lean principles. It focuses on:

- Waste Elimination: Removing unnecessary steps or resources.

- Value Enhancement: Concentrating on activities that add value to the customer.

- Streamlining Processes: Creating more efficient workflows.

- Continuous Improvement: Emphasizing regular evaluation and adaptation. Lean Six Sigma provides businesses with tools to optimize both quality and efficiency, meeting the dual demands of today’s competitive market.

Integrating DMAIC and Lean

When DMAIC and Lean are integrated, organizations can harness the combined power of quality improvement and waste reduction. This synergistic approach allows businesses to:

- Achieve Excellence: By focusing on quality (Six Sigma) and speed (Lean), companies can reach higher performance levels.

- Foster Collaboration: The structured methodologies enable cross-functional teamwork.

- Align with Strategy: The combined approach ensures alignment with strategic goals, enhancing overall business success. This integration fosters a culture of continuous improvement, adaptable to various corporate environments.

Benefits, Challenges, and Tips for Implementing Six Sigma

Benefits of Six Sigma

Implementing Six Sigma brings numerous benefits to an organization, including:

- Quality Improvement: Reducing defects and variations enhances product or service quality.

- Cost Reduction: Efficient processes lead to lower operational costs.

- Customer Satisfaction: Meeting customer requirements boosts satisfaction and loyalty.

- Strategic Alignment: Six Sigma helps align processes with organizational goals.

Challenges in Implementation

Despite its benefits, Six Sigma implementation can face challenges:

- Resistance to Change: Employees may resist new processes and methodologies.

- Lack of Resources: Insufficient training or budget constraints may hinder progress.

- Misalignment with Goals: If not aligned with business objectives, efforts may be counterproductive.

Practical Tips for Success

Successfully implementing Six Sigma requires careful planning and execution. Here are some tips:

- Secure Top Management Support: Gaining leadership buy-in ensures resources and prioritization.

- Train and Certify Staff: Investing in education at various belt levels builds competence.

- Align with Business Objectives: Ensure that Six Sigma initiatives align with the company’s strategic goals.

- Monitor and Adjust: Regularly evaluate progress and make necessary adjustments for continuous improvement.

Conclusion – Embarking on the Six Sigma Journey

Recap of Six Sigma Basics

Six Sigma offers a structured and data-driven approach to process improvement, focusing on quality enhancement and waste reduction. Through various belt levels, professionals can grow their expertise, contribute to projects, and drive organizational success. Combining Six Sigma with Lean principles further amplifies efficiency gains, making it a robust methodology for the corporate world.

The Path Ahead for Beginners

For those new to Six Sigma or considering it as a career or organizational strategy, understanding the different belt levels, responsibilities, certifications, and practical applications is crucial. The path to mastery involves:

- Learning the Basics: Starting with White or Yellow Belt training.

- Building Skills and Experience: Advancing to Green and Black Belts through hands-on projects and mentoring.

- Leading and Strategizing: Master Black Belts taking on strategic roles, shaping organizational excellence.

- Continuous Improvement: Embracing Lean Six Sigma principles for ongoing refinement.

Resources and Support

Various resources and training providers support the Six Sigma journey. Leveraging reputable certification bodies, engaging with mentors, joining Six Sigma communities, and continuously updating skills ensures success. Organizations can benefit from fostering a culture of continuous improvement and investing in employee development.

Subscribe to our newsletter!