Introduction

Embarking on a Six Sigma journey can be compared to setting sail in uncharted waters. With its proven methodology for process improvement and error reduction, Six Sigma provides a sturdy vessel for many organizations. One of the most crucial parts of this journey is the Control Phase, the final stage in the Six Sigma DMAIC (Define, Measure, Analyze, Improve, and Control) cycle. It is during this phase that the hard-won improvements are maintained and solidified, ensuring a long-lasting positive impact on the organization’s operations.

However, just as navigating a ship requires attention to shifting winds and currents, managing the Six Sigma Control Phase also comes with its set of challenges. These range from sustaining improvements and managing employee resistance to a lack of understanding about process control and data monitoring. But fear not, every challenge brings an opportunity for growth and learning. This article is designed to equip you with strategies to navigate these common hurdles effectively.

We will delve into the Control Phase of Six Sigma, outlining the common challenges that may arise, and most importantly, how to overcome them. We’ll also shine a light on three common mistakes made during this phase and provide insights on how to avoid them. The article will conclude with answers to frequently asked questions related to this topic, further enriching your understanding.

So whether you’re a Six Sigma beginner finding your bearings, or a seasoned practitioner looking to sharpen your skills, this comprehensive guide is sure to provide valuable insights to enhance your Six Sigma journey.

In This Guide

Understanding the Control Phase in Six Sigma

Stepping into the world of Six Sigma, we come across the DMAIC framework – an acronym for Define, Measure, Analyze, Improve, and Control. As the final step of this cycle, the Control Phase serves a pivotal role in the successful execution of Six Sigma projects. But what exactly is this Control Phase, and why does it hold such significance?

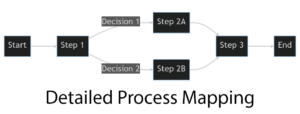

The Control Phase is where the rubber meets the road in a Six Sigma project. It is at this stage where the improvements identified during the Improve phase are solidified and maintained over time. The main objective is to ensure that the process continues to work efficiently even after the project has concluded. This is accomplished by developing and implementing a control plan, which includes monitoring the process, documenting changes, and training relevant personnel.

Moreover, the Control Phase is significant because it prevents the process from reverting to its previous state of inefficiency and errors. It’s like the captain of our ship continuously adjusting the vessel’s course to counteract the influence of waves and wind. Without these adjustments, the ship could easily drift off course. Similarly, without a robust Control Phase, the gains from a Six Sigma project could easily dissipate, causing the process to slip back to its old habits.

However, as straightforward as it may seem, the Control Phase is often misunderstood. A common misconception is that once the improvement actions have been implemented, the job is done. But in reality, the journey has just begun. Implementing changes is one thing; sustaining them over the long term is another. The Control Phase requires constant vigilance, adjustments, and refinement to ensure that improvements are enduring and the process remains in control.

In the upcoming sections, we’ll delve deeper into the common challenges that one may face during the Control Phase of Six Sigma and discuss practical strategies to overcome them. We’ll also explore three common mistakes to avoid ensuring your efforts yield the best possible results.

Common Challenges in the Control Phase of Six Sigma

Like a sailor navigating stormy seas, Six Sigma practitioners often encounter challenges during the Control Phase. These challenges, if not addressed promptly, can capsize your improvement efforts, steering your process back to its old, inefficient ways. Here are some common challenges faced during the Control Phase:

Challenge 1: Sustaining Improvements

The Control Phase’s ultimate goal is to sustain the improvements made, ensuring they stick long after the project has concluded. However, maintaining these improvements can be like trying to hold water in your hands—it requires ongoing effort and attention. Changes in personnel, lack of commitment from management, or even the pressure of daily operations can cause the process to slip back into old habits.

Challenge 2: Employee Resistance

Change, though necessary for improvement, is often met with resistance, especially if it disrupts established routines or requires additional effort from the employees. This resistance can be a significant hurdle in the Control Phase, making it challenging to implement and sustain the necessary changes.

Challenge 3: Lack of Understanding About Process Control

The Control Phase is not merely about maintaining the status quo. It involves a deep understanding of process control—knowing when to adjust the process and when to leave it alone. Without this knowledge, teams might overcontrol or undercontrol the process, both leading to undesirable results.

Challenge 4: Insufficient Data Monitoring

One of the key tasks in the Control Phase is monitoring data to verify the process’s performance. However, organizations often struggle with this, either due to lack of tools or skills required for efficient data monitoring.

Challenge 5: Inadequate Training

Training is crucial to equip employees with the knowledge and skills needed to support the new process. Inadequate training can lead to confusion, errors, and inefficiencies, all of which can jeopardize the Control Phase’s success.

These challenges may seem daunting, but fear not, for each problem, there’s a solution. In the next section, we will discuss strategies to navigate these challenges effectively, ensuring your Six Sigma project stays on course.

Navigating through the Challenges: Solutions

The challenges of the Control Phase in Six Sigma might seem like towering waves, but with the right strategies, you can steer your way through them. Here are some solutions to the challenges discussed in the previous section:

Solution to Challenge 1: Sustaining Improvements

Sustaining improvements requires constant vigilance and active management commitment. Ensure there is a Control Plan in place detailing what is to be controlled, how it will be controlled, and who is responsible. Regular audits and performance reviews can help identify any deviation from the plan, enabling timely corrective actions.

Solution to Challenge 2: Employee Resistance

Effective change management is key to overcoming resistance. Involve your team members from the onset of the project, soliciting their input and feedback. By doing so, you foster a sense of ownership and reduce resistance. Moreover, communicate the benefits of the changes, demonstrating how they contribute to overall process efficiency and individual job roles.

Solution to Challenge 3: Lack of Understanding About Process Control

Providing education and training on process control is crucial. It’s also beneficial to use statistical process control charts, which allow teams to visualise process performance over time and make informed decisions about when adjustments are necessary.

Solution to Challenge 4: Insufficient Data Monitoring

Invest in reliable data collection and monitoring tools, and train your team on their proper usage. Remember, the quality of your data plays a significant role in the success of your Six Sigma project.

Solution to Challenge 5: Inadequate Training

Ensure that all relevant personnel receive proper training on the new process and their roles within it. Regular refresher courses can help to reinforce the knowledge and maintain skill levels.

By equipping yourself with these strategies, you can turn the tide on the challenges of the Control Phase. However, it’s not just about overcoming challenges; avoiding common mistakes is equally important. In the next section, we’ll discuss three common mistakes in the Six Sigma Control Phase and how to avoid them.

Three Common Mistakes in the Six Sigma Control Phase and How to Avoid Them

Every journey has its pitfalls, and the Six Sigma journey is no exception. While we’ve discussed various challenges and their solutions, there are also specific mistakes that practitioners often make during the Control Phase. Let’s shed light on these errors and discover ways to prevent them.

Mistake 1: Not Properly Training and Engaging Team Members

Training and engagement are vital to the success of any change initiative, including Six Sigma. Yet, it’s common for organisations to rush this process or neglect it altogether, resulting in confusion and resistance among team members.

How to Avoid It: Make training an integral part of your Control Phase. Use a variety of training methods to cater to different learning styles and ensure that everyone understands their role in maintaining the improved process. Engage your team by regularly communicating progress, acknowledging their contributions, and celebrating successes.

Mistake 2: Neglecting the Control Plan

A ship without a compass is bound to get lost. Similarly, neglecting the control plan — your project’s compass — can lead your process astray.

How to Avoid It: Develop a comprehensive control plan that clearly outlines what needs to be controlled, the methods for control, and who’s responsible. Treat this plan as a living document, adjusting it as necessary based on the process performance data.

Mistake 3: Overlooking the Importance of Documentation

Documentation, often seen as a tedious task, is frequently overlooked. However, failing to document changes, decisions, and procedures can lead to inconsistency and confusion.

How to Avoid It: Make documentation a standard practice in your Control Phase. This should include changes made, procedures for new processes, roles and responsibilities, and any decisions taken along the way. Documentation serves as a valuable reference for your team and can be highly beneficial for future training and improvement efforts.

By avoiding these common mistakes, you’re one step closer to a successful and effective Six Sigma Control Phase. But the learning doesn’t stop here. In the next section, we answer some frequently asked questions about the Control Phase, further enhancing your understanding.

Frequently Asked Questions about the Six Sigma Control Phase

To further enrich your understanding, let’s address some frequently asked questions about the Control Phase in Six Sigma.

What does a control plan in Six Sigma include?

Answer: A control plan in Six Sigma is a detailed document that outlines how the process will be controlled and maintained. It typically includes the process input and output variables that need to be controlled, the methods for control, measurement systems, the individual or team responsible for the control, and the process for responding to deviations.

How long does the Control Phase in Six Sigma last?

Answer: The Control Phase in Six Sigma lasts as long as the process is running. It’s not just a phase that ends after a project’s completion; it’s a continuous process of monitoring, controlling, and improving to maintain the achieved gains.

Why is statistical process control essential in the Control Phase?

Answer: Statistical process control is a method of using statistical techniques to control a process. It’s vital in the Control Phase as it provides a visual method for monitoring process performance, identifying variations, and determining whether they’re due to common or special causes. This information is crucial for making informed decisions about process adjustments.

What role does leadership play in the Control Phase?

Answer: Leadership plays a pivotal role in the Control Phase. Leaders are responsible for championing the changes, securing resources, resolving resistance, and ensuring the process stays on course. Their commitment and active involvement can greatly influence the success of the Control Phase.

How does the Control Phase contribute to continuous improvement in Six Sigma?

Answer: The Control Phase contributes to continuous improvement by ensuring that the process is monitored and adjusted as necessary to maintain the improvements. This phase establishes a feedback loop that allows for ongoing refinement, laying the groundwork for continuous improvement.

Hopefully, these questions and answers have given you a deeper understanding of the Control Phase’s intricacies in Six Sigma. It’s crucial to remember that the Control Phase, with its challenges and potential for mistakes, is a significant part of the Six Sigma journey. With the knowledge and strategies provided in this article, you are better equipped to navigate these waters successfully.

Final Thoughts

The Control Phase in Six Sigma, while challenging, is a vital part of ensuring the sustainability of improvements. It is the final line of defense against inefficiencies and process variations, protecting the gains achieved throughout the Six Sigma project.

Navigating the Control Phase successfully requires a deep understanding of its importance and a keen awareness of the challenges that lie ahead. It calls for effective strategies to sustain improvements, overcome employee resistance, understand process control, and ensure efficient data monitoring and training. Equally important is the knowledge to sidestep common mistakes, such as inadequate training, neglecting the control plan, and overlooking documentation.

The road may seem daunting, but armed with these insights and strategies, you’re well-equipped to journey through the Control Phase. The voyage may be marked with trials, but each challenge overcome is a step towards greater efficiency, improved processes, and, ultimately, superior quality.

As you apply what you’ve learned in this article, remember that Six Sigma is a journey of continuous improvement. Each phase, each challenge, and each success is a stepping stone towards operational excellence. So embrace the journey, knowing that every effort brings you closer to your goal.

Are you ready to take the next step in your Six Sigma journey? If you found this article helpful, we have something even more comprehensive and insightful for you! Dive deeper into the world of Six Sigma with our extensive guide on the DMAIC process.

Our guide provides a thorough exploration of each phase, complete with real-world examples, tips, and strategies to ensure your Six Sigma project is a resounding success. So why wait? Let’s navigate the path to continuous improvement together.